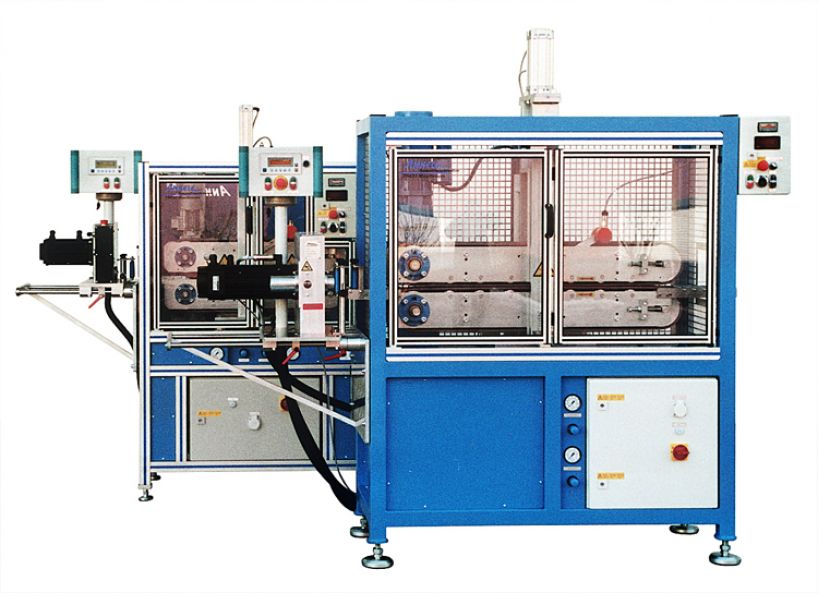

Cutting Unit / Servocutter ASC

With this Ankele machines ASC 20 and ASC 50 we extend our proven machine program within the range non–cutting separation from plastic / rubber profiles, tubes, optical waveguide cables etc.

The servo motor with flanged on cut medium implements a 360° rotation with adjustable speed, at which the profil is separated. The for the cut execution necessary impulse comes from an rotation transductor which runs along the cutting profil. As cutting medium different polystyrene blade or special Cutter measurer can be used.

The change–over from clock pulse use to permanent use (rotating) happens automatically and is lengthen– and speed–dependently. The complete cutting unit can be shifted approximately 300 mm in extruding direction. Most likely, this will improve the starting process of the cutting line. The separately standing, mobile switchgear cabinet is plugged to the swivelling control cabinet. This makes it simpler to integrate the machine into existing extruding lines. You can also use the machine as a stand alone device.

ASC 20 suitably for smaller hard soft profiles or thin–walled tubing/hoses which a cross section of 25– max.32mm do not exceed.

ASC 50 suitably for middle hard soft profiles or thin–walled tubing/hoses which a cross section of 50mm do not exceed.

Further extras such as conveyor belts etc. or special customized solutions on request.

Trenneinrichtung2.jpg(45 KB)

Trenneinrichtung2.jpg(45 KB)

Extruder

Contact

Ankele Kunststoffmaschinenbau

Inhaber Ulrich Ankele

Daimlerstraße 42

75433 Maulbronn

Copryright: Ankele Kunststoffmaschinenbau, Maulbronn